Stop Shipping Air.

Optimize in Milliseconds.

As the fulfillment engine for Intelligent Automation 3.0, Packem moves beyond simple box-fitting. It utilizes Center of Gravity (CoG) awareness to ensure load stability, accounts for the real-world cost of filling materials, and provides instant CO₂ emission analytics to help you build a smarter, more sustainable supply chain.

Other Static Solvers

Treats Shipment #10,000 exactly like Shipment #1. It never learns from your data.

Optimizes for geometry (Tetris) but ignores gravity, causing damaged goods.

Stability-First Intelligence

Packem doesn't just find a fit; it finds a balance. By automatically placing high-density items at the base and calculating the optimal Center of Gravity (CoG), Packem ensures stable pallets and containers, reducing damage and transit risks.

Eliminate Wasted In-Box Air

Stop paying to ship plastic filler. Packem calculates the exact cost of filling materials and selects the smallest possible container from your inventory. This reduces dunnage waste and slashes Dimensional Weight (DIM) surcharges.

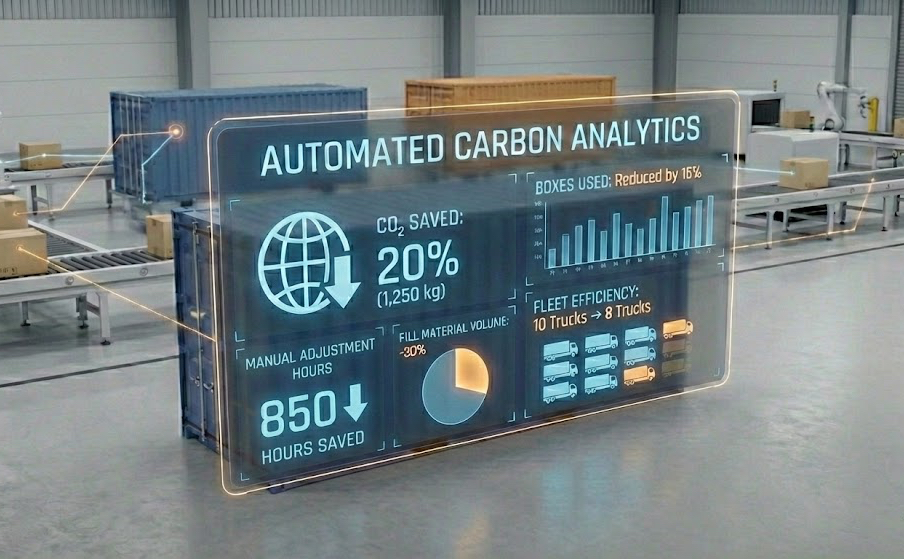

Automated Carbon Analytics

Transform space utilization into a sustainability asset. Packem provides real-time CO₂ emission estimates based on your packing density. Maximize every cubic inch of your fleet to reduce trip frequency and your carbon footprint.

ROI You Can Measure

We benchmarked Packem against standard manual packing processes using 5,000 mixed-SKU payloads. The result is efficiency you can see on the bottom line.

Integration Roadmap

The Cost of Shipping Air

Adjust the slider to your monthly logistics spend to see how Packem's density optimization impacts your bottom line and your carbon footprint.